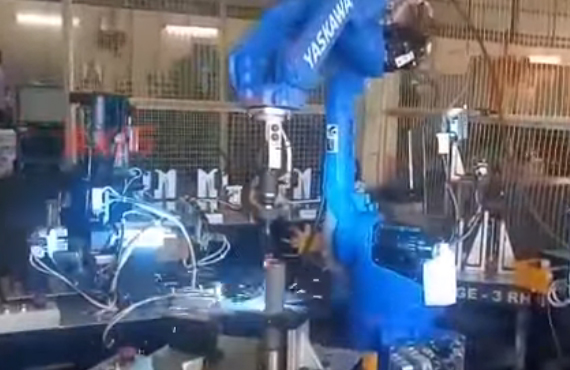

Welding

Benefits Of Robotic ARC Welding

- High Quality and more consistent welds

- Higher Production Speed

- Reduced Scrap Rates

- Employee Safety-Reduce employee injury claims

- Lower Operations cost

Advancements in welding technology and reduced equipment costs have made robotic welding affordable to a large range of manufacturers. AGA offers a complete welding solution, from design to installation, and after-the-sale customer service. We partner with you to design and create a solution that enhances your production line and improves the working environment in your facility.

Why Choose AGA for ARC Welding

- Process Knowledge

- Experienced robotic welders

- Vision guided arc welding

- GTAW, PAW, GMAW, SAW, Mig, and Tig welding options

- Aluminum arc welding experience

- Multi-robot custom-built systems

- Tooling

- Custom tooling designs

- Easy to load tooling

- Wear-resistant materials

- Flexible fixtures

- 3-D CAD-CAM tool design & build

- Proven Designs

- Pre-engineered robot welding cells

- Standard positioners

- Industry-standard weld systems

- Independent robot selection

Spot Welding

- High-speed, precision robots for efficient spot welding

- Reduce cycle time by 20% with greater spot control

Spot welding is a resistance welding process that uses large electrical current to join two or more sheets of metal in a single location. Spot welding technology has evolved through its extensive use in automobile manufacturing using articulated robots. AGA is pushing the envelope by developing spot welding automation that offers through arm cable routing, reduces cycle time, allows greater control, and reduces cost.

Manufacturers who apply robotic spot-welding robots immediately see advantages as compared to a manual process, including:

- More cost-effective

- Weld consistency

- Ability to reach difficult welds

- Higher repeatability

- Floor space savings